Skip to product grid

-

Digital Thermostat 8820 with NTC Sensor – Temperature Controller -50°C to +150°C

Regular price £27.60Regular price -

Silicone Adhesive Patch K Thermocouple Sensor

Regular price £12.60Regular price -

Novus N321 Electronic Thermostat, J/K

Regular price £44.40Regular price -

Thermocouple Sensors- K probes 3mm Dia 50- 300mm lg

Regular price From £12.60Regular price -

PT100/RTD Temperature Sensors 3mm Dia

Regular price From £13.20Regular price -

PT100/RTD Temperature Sensors 6mm Dia

Regular price From £12.60Regular price -

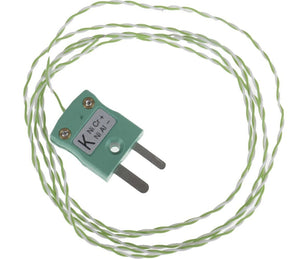

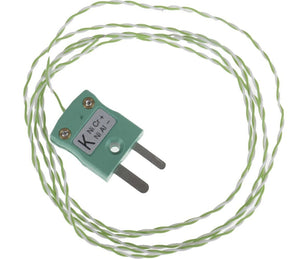

Type K Thermocouple Plug and 1.5m Exposed Tip

Regular price £5.40Regular price -

Thermocouple Sensors- K probe - 6mm Dia - 50-150mm Long

Regular price From £15.24Regular price -

Compression Gland 316 S.ST 3/8"x 6mm BSPP

Regular price £6.00Regular price -

N1030T PID Controller & Timer SSR/Relay Output

Regular price £48.60Regular price -

Thermowell Sensor Pockets – Sizes 100mm to 200mm

Regular price From £9.60Regular price -

Novus N321 Electronic Thermostat, J/K, 12/24V

Regular price £44.40Regular price -

Boiler Timer Switch for Ravenheat & Ferroli

Regular price £14.40Regular price -

Thermocouple Bayonet Sensor – Type J/K, 4.8 x 13mm Probe with 200mm Adjustable Spring

Regular price £12.48Regular price -

Sold out

Digital Thermostat 8820 PTC sensor

Regular price £28.80Regular price -

N1030 PID Controller SSR/Relay Output

Regular price £54.00Regular price -

Novus N321 Electronic Thermostat, PT100, 12/24V

Regular price £44.40Regular price -

60min Dial Timer Delay Switch

Regular price £15.60Regular price -

Leaf Thermocouple Sensor

Regular price £14.40Regular price -

Thermocouple Sensors- J probes 3mm Dia 50- 500mm lg

Regular price From £12.60Regular price -

Novus N322 PID Controller PT100, 240V, Relay/Relay

Regular price £50.40Regular price -

Thermocouple Type K 3mm x 50mm 2.5m s.st braided leads

Regular price £12.00Regular price -

Novus N322 PID Controller J/K/T, 240V, SSR/Relay

Regular price £50.40Regular price -

Novus N322 Electronic Thermostat PT100, 240V, Relay/Relay

Regular price £50.40Regular price -

K/J Type Thermocouple Plug & Sockets

Regular price From £4.80Regular price -

Compression Gland 316 S.ST 1/8"x 3mm BSPP

Regular price £6.00Regular price -

Compression Gland 316 S.ST 1/2"x 6mm BSPP

Regular price £6.00Regular price -

Silicone Patch K Thermocouple Sensor

Regular price £14.40Regular price -

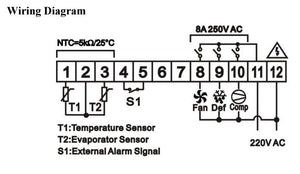

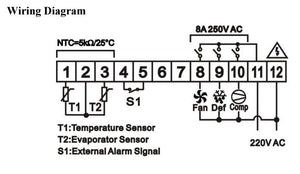

Digital Thermostat 6830 3 Outputs

Regular price £33.60Regular price -

RHT Climate Relative Humidity & Temperature Transmitter NOVUS-WM RS485

Regular price £186.00Regular price -

Din Rail USB Temperature Transmitter NOVUS TxRail-USB

Regular price £64.80Regular price -

N1040 PID Temperature Controller USB

Regular price £54.00Regular price -

Thermocouple wire type J & K

Regular price From £8.74Regular price -

J/K Type Thermocouple – Thin Washer Style, 10mm OD / 6.5mm ID, 2m Leads

Regular price £11.40Regular price -

Chip Scuttle Heating Element

Regular price £56.16Regular price -

Compression Gland 316 S.ST 1/8"x 6mm BSPP

Regular price £6.00Regular price