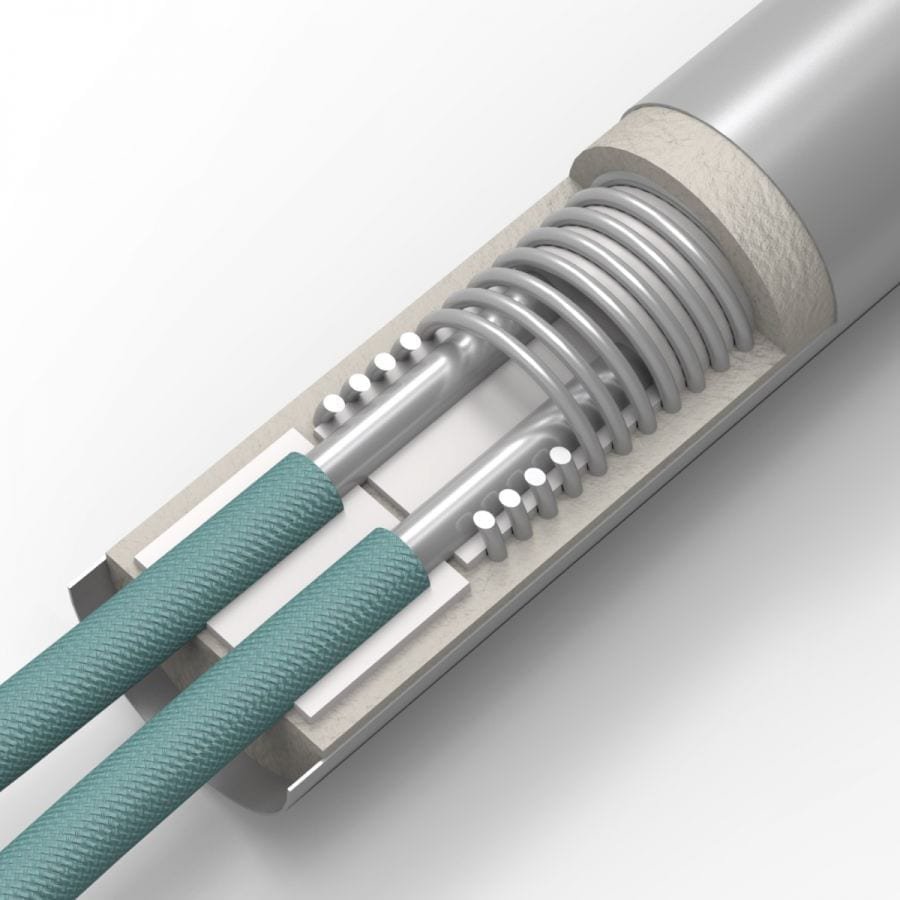

The UCI cartridge heater range provides excellent heat transfer and long life. Cartridge heaters are designed for a push-fit into holes of nominal diameters. They are manufactured to the highest standards and from the highest quality materials. The primary use of cartridge heaters is for heating Dies, Moulds, Platens and various other applications demanding localised heating. They can be designed to operate up to 800 deg C.

Cartridge heaters are available in metric and imperial sizes 6.5mm (1/4″) to 40mm (1.5″) diameters and up to 2m in length.

Supplied as high watt densities as standard for the most demanding of applications, medium and low are also offered on request.

Several factors must be considered when selecting the proper cartridge heater, such as below, that will ensure your heaters last as long as possible and perform as required.

products

Cartridge Heater Calculator

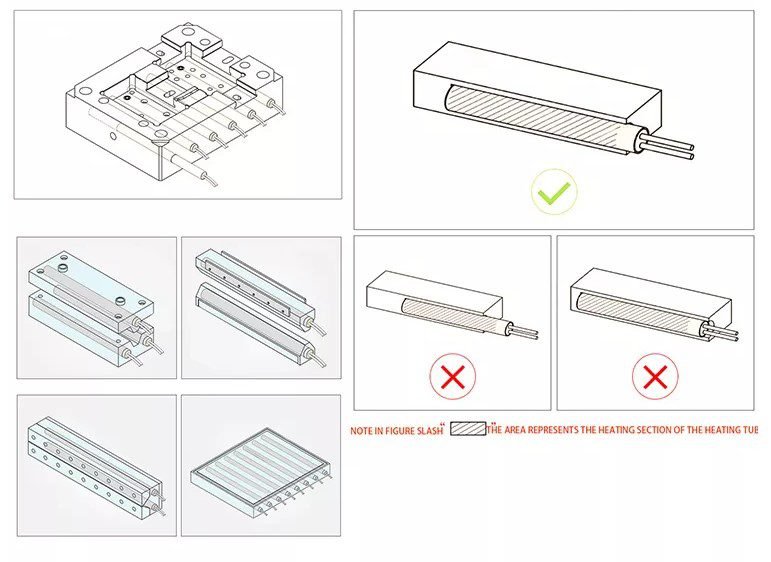

Correct Installation Guide for Cartridge Heaters

Useful Power Calculator

Surplus stock cartridge heaters

| Stock Code | Qty | Diameter | Length | Wattage | Voltage | Lead Length | Extra info | |

|---|---|---|---|---|---|---|---|---|

| CH650250230 | 5 | 6mm | 50mm | 250 | 230 | 1000 | 7.50 | |

| CH653015042-EUROSLOT | 4 | 6.5mm | 30mm | 150 | 42 | 300 | Angled Exit | 6.50 |

| CH10150500220 | 1 | 10mm | 150mm | 500 | 220 | 300 | 8.00 | |

| CH12280400230 | 12 | 12mm | 280mm | 400 | 230 | 200 | Armoured leads | 13.00 |

| CH12565600220 | 1 | 12.5mm | 65mm | 600 | 220 | 300 | 7.50 | |

| CH12580500230 | 6 | 12.5mm | 80mm | 500 | 230 | 350 | stainless overbraid | 6.00 |

| CH125100400230 | 20 | 12.5mm | 100mm | 400 | 230 | 300 | 6.00 | |

| CH1255250240 | 28 | 1/2" | 5.5" | 250 | 240 | 400 | 6.00 | |

| CH128250240ANG | 10 | 1/2" | 8" | 250 | 240 | 1000 | stainless overbraid, angled | 11.00 |

| CH15300300240ANG | 3 | 15 | 300mm | 300 | 240 | 1500 | Angled Exit | 12.00 |

| CH1675400220 | 1 | 16mm | 75mm | 400 | 220 | 300 | 7.50 | |

| CH1663175230 | 3 | 16mm | 63mm | 175 | 230 | 1000 | 8.00 | |

| CH16300650240 | 4 | 16mm | 300mm | 650 | 240 | 200 | 11.00 | |

| CH583175240ANG | 5 | 5/8" | 3" | 175 | 240 | 2000 | Angled Exit | 9.00 |

| CH586635240 | 10 | 5/8" | 6" | 635 | 240 | 200 | 9.00 | |

| CH125125500230ANG | 20 | 12.5mm | 125mm | 500 | 230v | 750mm | Angled exit , SSOB | 16.00 |

0121 238 2795

0121 238 2795

Free Shipping

Order by 1 pm for same-day dispatch

Free Shipping

Order by 1 pm for same-day dispatch Technical support

Free tech support

Technical support

Free tech support Secure payment

Fast and easy payment options

Secure payment

Fast and easy payment options Price Guarantee

We will beat any like for like quotation

Price Guarantee

We will beat any like for like quotation